Using Produced Water

Recycling oilfield water in the oil and gas industry and beyond

Opportunities and Concerns in Using Produced Water

Produced water is natural groundwater that is extracted along with oil and gas. It is commonly salty and mixed with oil residues,1 so it must be either disposed of or treated and reused. About 2.5 billion gallons of produced water are extracted every day from all types of oil and gas wells, including coalbed methane wells.2 If treated appropriately, produced water may be a valuable water source for agriculture, industry, and energy production,3,4 but currently less than one percent of produced water is reused outside the oilfield.5 This is due both to the high cost of treatment and to public concerns over the environmental and human safety of produced water.

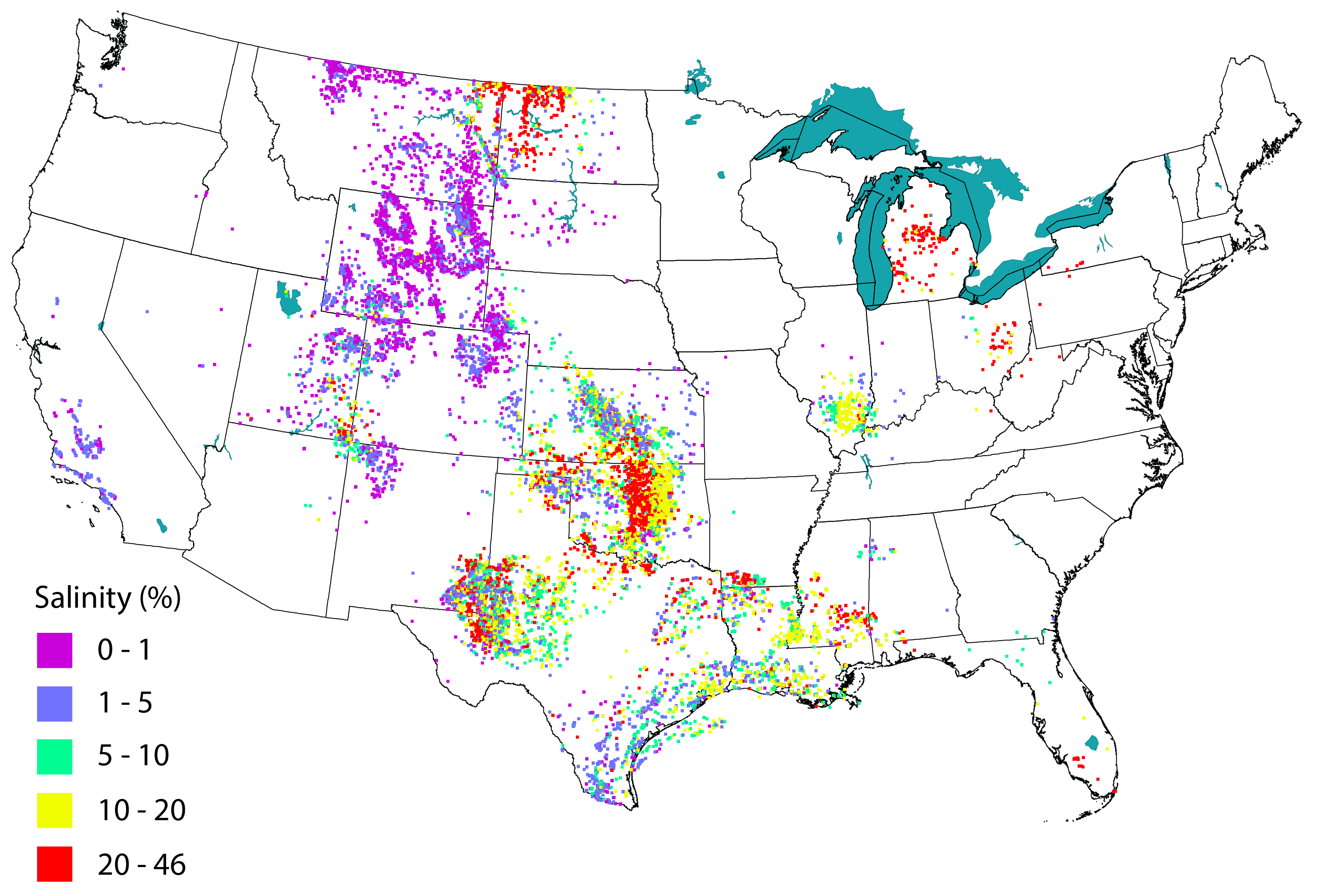

Salinity (total dissolved solids) of produced waters in the United States. The composition of produced water depends strongly on where it comes from and influences options for treatment and reuse. For comparison, seawater has a salinity of 3.5%. Image credit: Tracey Mercier, U.S. Geological Survey

Chemistry and Quantity of Produced Water Determine its Fate

Produced water reuse depends on the water’s chemistry and quantity, the cost of treatment, transportation, and storage, and state and federal regulations. Produced water can contain varying amounts of dissolved oil and gas, toxic chemicals such as benzene, naturally occurring radioactive material, and dissolved solids or salts. The chemistry and quantity of produced water vary greatly from place to place and may also vary over the lifetime of a single well.

The salinity of produced water, a major constraint on reuse, ranges from nearly fresh (≤1%) to about 50% – 15 times saltier than seawater. Most produced water is currently disposed of in deep underground injection wells,2 so access to disposal wells may also influence reuse decisions: in 2015, Texas had about 8,100 active oilfield wastewater disposal wells,6 but in 2017, Pennsylvania had only 11 wells permitted for this purpose.7 Under the Safe Drinking Water Act, underground injection of oil- and gas-related fluids for disposal or enhanced oil recovery is regulated by the EPA for nine states (including two oil-producing states: Pennsylvania and Virginia) or individually by the 41 states and two tribes to which the EPA has delegated authority.8

Produced Water Treatment

Before being reused, produced water must be treated to remove oil residues, salts, suspended solids, and other chemicals. The level of treatment required depends on what the water will be used for. When reusing produced water for new hydraulic fracturing operations, often relatively little treatment is required.5 For irrigation or groundwater recharge, most of the salt must be removed. The more treatment required, the more expensive the process; it is possible to produce distilled water from produced water, but this would be very expensive. New technologies are continuously being developed and refined; for example, methods are being developed to remove boron, which is toxic to plants and can degrade some gels used for hydraulic fracturing.5

Reuse in the Oil and Gas Industry

- By far the most common application for reusing produced water is for injection into oil-producing formations to enhance oil production. Nationally, about 45% of all produced water is reused for this purpose.2

- In the Marcellus shale of Pennsylvania, West Virginia, and surrounding states, high water demand for hydraulic fracturing but low produced water volumes mean that almost all produced water is reused for hydraulic fracturing. Produced water only provides about 15% of the water needed to fracture new wells; the rest of the water comes largely from fresh surface waterbodies.9

- In the Permian basin of West Texas, companies that operate large numbers of wells reuse millions of gallons of produced water. Centralized treatment and storage facilities served by a network of pipelines help to reduce truck traffic and associated emissions and road damage.2

Depending on the level of treatment, produced water may be used for many purposes. Some recent examples include:

- Thousands of acres in the Powder River Basin (Wyoming and Montana) are irrigated using treated produced water from coalbed methane wells to restore overgrazed range land or produce livestock forage. Some treated coalbed methane water is used to provide drinking water for livestock and wildlife.10

- In Wellington, Colorado, treated produced water is used in an aquifer storage and recovery project to maintain groundwater supplies in the region.11

- In California, low-salinity produced water is reused for enhanced oil recovery, groundwater recharge, and agriculture. Of the 80 billion gallons of oilfield water produced in California in 2013, about 20% (entirely from wells that are not hydraulically fractured) was treated and used for irrigation of crops for human consumption. State regulations specifically prohibit the use of water from hydraulically fractured wells to irrigate food crops.12

- Some states allow the spreading of highly saline produced water on roads for winter ice control.13,14 The EPA recommends against this practice because the water may contain other pollutants in addition to salt.15

A Complicated Legal Framework

If produced water has economic value (as a water or mineral source rather than a waste product), its reuse is complicated by water rights laws and regulations, which vary from state to state. Another legal concern for production companies is liability for the reused water, which, depending on the level of treatment, may be unsuitable for certain uses.5

More Resources

U.S. Geological Survey – National Produced Waters Geochemical Database.

National Academies of Science, Engineering, and Medicine (2017). Flowback and Produced Waters: Opportunities and Challenges for Innovation: Proceedings of a Workshop. Washington DC: The National Academies Press.

References

1 U.S. Geological Survey – National Produced Waters Geochemical Database.

Accessed from:

2 Veil, J. (2015). U.S. Produced Water Volumes and Management Practices in 2012.

Accessed from: http://www.veilenvironmental.com/publications/pw/prod_water_volume_2012.pdf

3 Oklahoma Water Resources Board – Water for 2060 Produced Water Working Group. https://www.owrb.ok.gov/2060/pwwg.php

Accessed from:

4 Colorado School of Mines Advanced Water Technology Center – Produced Water Beneficial Use Case Studies.

Accessed from: http://aqwatec.mines.edu/produced_water/assessbu/case/

5 National Academies of Science, Engineering, and Medicine (2017). Flowback and Produced Waters: Opportunities and Challenges for Innovation: Proceedings of a Workshop. Washington DC: The National Academies Press.

Accessed from: https://www.nationalacademies.org/publications/24620

6 Railroad Commission of Texas – Injection and Disposal Wells. https://www.usgs.gov/tools/us-geological-survey-national-produced-waters-geochemical-database-viewer

Accessed from: http://www.rrc.state.tx.us/about-us/resource-center/faqs/oil-gas-faqs/faq-injection-and-disposal-wells/

7 PA DEP approved 11th underground injection well for oil and gas waste. J. Hurdle, NPR StateImpact, June 5, 2017.

Accessed from: https://stateimpact.npr.org/pennsylvania/2017/06/05/pa-dep-approved-11th-underground-injection-well-for-oil-and-gas-waste/

8 U.S. Environmental Protection Agency – Protecting Underground Sources of Drinking Water from Underground Injection (UIC).

Accessed from: https://www.epa.gov/uic

9 Vidic, R.D. and Yoxtheimer, D. (2017). Changes in the Quantity and Quality of Produced Water from Appalachian Shale Energy Development and their Implications for Water Reuse. Presentation at the Pennsylvania State University Marcellus Center for Outreach and Research.

Accessed from: http://www.shalenetwork.org/sites/default/files/Vidic_2017_ShaleNetwork.pdf

10 Colorado School of Mines Advanced Water Technology Center – Produced Water Beneficial Use Case Studies.

Accessed from: http://aqwatec.mines.edu/produced_water/assessbu/case/

11 National Research Council (2010). Management and Effects of Coalbed Methane Produced Water in the Western United States. Washington, DC: The National Academies Press.

Accessed from: https://www.nap.edu/catalog/12915/management-and-effects-of-coalbed-methane-produced-water-in-the-western-united-states

12 California State Water Resources Control Board (2016). Frequently Asked Questions About Recycled Oilfield Water for Crop Irrigation.

Accessed from: https://www.waterboards.ca.gov/publications_forms/publications/factsheets/docs/prod_water_for_crop_irrigation.pdf

13 North Dakota Department of Health – Guidelines for the Use of Oilfield Salt Brines for Dust and Ice Control.

Accessed from: https://deq.nd.gov/Publications/WQ/IceDustControlUsingOilfieldBrine_20130321.pdf

14 1509.226: Surface applications of brine by local governments. Ohio Revised Code, Title XV: Conservation of Natural Resources, Chapter 1509: Division of Oil and Gas Resources Management – Oil and Gas.

Accessed from: http://codes.ohio.gov/orc/1509.226

15 Poole, H. (2013). State Policies on Use of Hydraulic Fracturing Waste as a Road Deicer. Connecticut Office of Legislative Research.

Accessed from: https://www.cga.ct.gov/2013/rpt/2013-R-0469.htm

16 Schnebele, E. (2016). Iodine. 2015 Minerals Yearbook, U.S. Geological Survey.

Accessed from: https://minerals.usgs.gov/minerals/pubs/commodity/iodine/myb1-2015-iodin.pdf

Flowback Water

In addition to naturally occurring produced water, some of the water that comes up a hydraulically fractured oil or gas well is flowback of the previously injected hydraulic fracturing fluid.

Mining Resources from Produced Water

Treatment of produced water typically involves removing a wide variety of dissolved salts and other compounds to improve the quality of the water. Some of these compounds may themselves have value; for example, several Oklahoma operations extract and sell iodine from highly saline produced water.16 Other potentially valuable elements, such as lithium, also occur in produced water, but extraction of most elements is not currently economical.

Table of Contents

- #1: Petroleum and the Environment: an Introduction

- #2: Water in the Oil and Gas Industry

- #3: Induced Seismicity from Oil and Gas Operations

- #4: Water Sources for Hydraulic Fracturing

- #5: Using Produced Water

- #6: Groundwater Protection in Oil and Gas Production

- #7: Abandoned Wells

- #8: What Determines the Location of a Well?

- #9: Land Use in the Oil and Gas Industry

- #10: The Pinedale Gas Field, Wyoming

- #11: Heavy Oil

- #12: Oil and Gas in the U.S. Arctic

- #13: Offshore Oil and Gas

- #14: Spills in Oil and Natural Gas Fields

- #15: Transportation of Oil, Gas, and Refined Products

- #16: Oil Refining and Gas Processing

- #17: Non-Fuel Products of Oil and Gas

- #18: Air Quality Impacts of Oil and Gas

- #19: Methane Emissions in the Oil and Gas Industry

- #20: Mitigating and Regulating Methane Emissions

- #21: U.S. Regulation of Oil and Gas Operations

- #22: Health and Safety in Oil and Gas Extraction

- #23: Subsurface Data in the Oil and Gas Industry

- #24: Geoscientists in Petroleum and the Environment

- Glossary of Terms

- Full Reference List